Δείτε όλα τα προϊόντα της μάρκας

Δείτε όλα τα προϊόντα της μάρκας

Direct Flow Reverse Osmosis Pentair PRF-RO GE MERLIN USA

Reverse osmosis system Pentair PRF-RO 350 GE MERLIN. Maximum production up to 2,600 liters per day in a Compact construction with complete connection materials and the possibility of vertical or horizontal installation. Made in USA

Made in USA Continuous System tankless flow

Continuous System tankless flow No electricity required

No electricity required

The American company Pentair leads the way again by manufacturing a reverse osmosis system with its subsidiary company General Electric, the Pentair PRF-RO GE MERLIN. It is the only reverse osmosis system that can produce osmotic water without a pressure pump, therefore without electricity and other moving parts. It does not require a water storage tank and at the same time is very easy to install and maintain.

Merlin Uses 2 TLC-350 High Flux membranes of special high recovery technology with low water rejection and high salt rejection.

The system is made entirely in USA!!

With a minimum operating pressure of 2.8bar and 750ppm TDS it is capable of producing 1 liter per minute and can reach up to 2,600 liters per day depending on the operating pressure.

Advantages

- Continuous flow system without the need to store water

- It does not require a water storage tank

- It does not require electricity

- It works with a low pressure of 2.8 bar

- 93% average descaling at 5.5 bar

- Water production up to 2,600 liters per day

- Up to 75% less waste water compared to common systems

- Easy filter replacement without tools

- High quality heavy duty containers

- Possibility of horizontal or vertical placement

- Made in America

- Compact construction

- Fibredyne technology active carbon prefilter for up to 38,000 liters

- 2 TLC-350 high flux membranes

Lots of Apps

- Steamers

- Humidifiers

- Coffee makers

- Ice makers

- Aquariums

- Photography processing

- Misters

- Water coolers

- Ho.Re.Ca solutions Hotels-Restaurants-Coffee-Pubs

- Business offices

- and many other applications.

The System Consists of:

1 Fibredyne technology active carbon filter

2 TLC-350 reverse osmosis membranes

1 in-line line filter

Faucet

Fittings (color-coded tubing, John Guest fasteners, flange lubricants, etc.)

Special filter replacement key which is part of the base

Instructions for use

Filter Replacement Frequency:

1st Stage: Fibredyne technology active carbon filter to remove chlorine, VOCs, solid particles, etc. Change every 12 months or 38,000 litres

2nd Stage: 2 Pentair TLC-350 High Flux membranes with a total production of 700GPD (2,600 liters per day). Change from 2 to 3 years

3rd Stage: Post Filter line active carbon filter. Replace every 12 months.

4th Stage: Optional Filtrato Mineralization trace element enrichment filter. Change every 12 months

Operating Conditions

Operating pressures from 2.76 bar (40 psi) to 5.52 bar (80 psi)

Operating temperature from 4.44°C (40°F) to 37.78°C (100°F)

Total Solids TDS up to 2,000 mg/L

Hardness up to 171 mg/L – (10 grains)

Chlorine up to 1.0 mg/L

Iron up to 0.1 mg/L

Manganese up to 0.05 mg/L

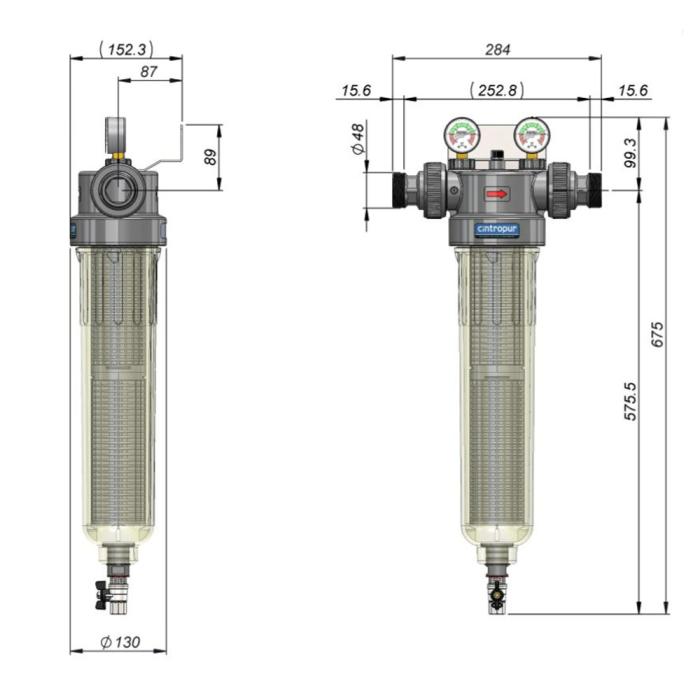

Dimensions