Δείτε όλα τα προϊόντα της μάρκας

Δείτε όλα τα προϊόντα της μάρκας

Vontron ULP1812-100 GPD Reverse Osmosis Membrane

Vontron Technology high scale rejection membrane for reverse systems osmosis system with high clean water requirements. 100GPD Reverse Osmosis Membrane

100GPD Reverse Osmosis Membrane 99% descaling

99% descaling  NSF 58 Certification

NSF 58 Certification

High quality film from the world's leading film manufacturer.

Thanks to its American technology, Vontron exclusively manufactures reverse osmosis membranes, with a research and development department that has 130 patents and another 50 pending.

It has a fully automated production plant of over 3,000m2 and exports to over 130 countries and is NSF58 certified.

Vontron ULP1812-100 unique technology with 99% descaling

The membrane has a production capacity of 100GPD (378lt per day) with a pore size of 0.0001micron.

Advantages

- 99% descaling. The highest rejection rate on the market

- NSF 58 certified

- 20% more operating flow than the competition

- Fixation time under 30 minutes

- Excellent performance even in hard water

- The membrane design does not easily allow fouling to form inside. This gives the membrane longer life and less maintenance

- It is compatible with all 1812 membrane cases

- Authentication via 20-digit serial number

Certificate of Authenticity

Each film has a unique number with which you can be sure that your film is a genuine VONTRON.

You can register at the following link: http://track.vontron.com/

Technical Characteristics

Membrane type | ULP1812-100 |

Construction material | spiral-wound element with polyamide thin-film composite |

Country of manufacture | China |

Certification | NSF/ANSI 58 |

Daily water production* | 378 lt/d |

Water production per hour* | 15.7 lt/h |

Salt Rejection* | 99.0 % |

Maximum working pressure | 10 bars |

Maximum operating temperature | 45°С |

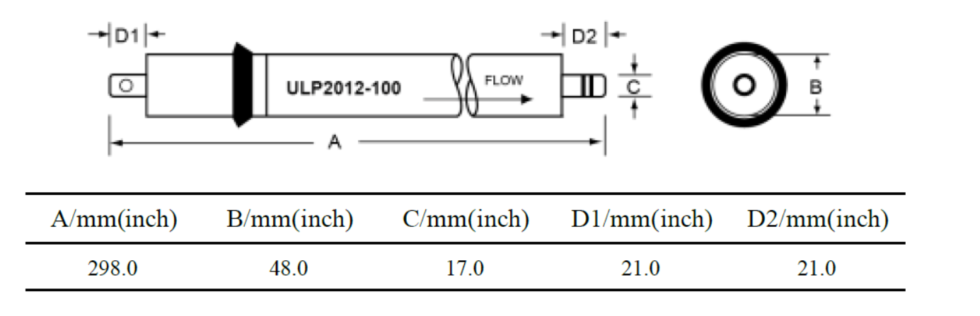

Diaphragm dimensions including orifices (length x diameter) | 298mm X 48mm |

Water outlet dimensions (length x diameter) | 21mm X 17mm |

Delivery of Membrane | Dry in Sealed package |

1. Permeate flow and salt rejection based on the following test conditions: 250 ppm NaCl, 25°C, pH 6.5 – 8.5 15% recovery and the specified applied pressure 60psi.

2. Minimum salt rejection is 96.0%.

3. Permeate flows for individual elements may vary ±20%.

Dimensions